30 years of designing optical systems for automotive, medical and general lighting: the experience of a life to create superior optical solutions.

OPTICAL SYSTEMS DESIGN

Area Luce designs and manufactures optical components and systems targeted for the automotive, aerospace, medical and industrial sectors.

The company was established in 2020, evolving from the previous “Optical Design Center” (O.D.C), a consulting firm which had been operating since 2010 in the field of design and development of optical and opto-mechanic systems and components.

We aim to provide both optical design services and manufacturing, offering our customers a comprehensive solution that covers everything from concept development and feasibility assessment to the final product—whether single components or complex systems

To this end, we cooperate with highly-qualified partners and supply companies. Thanks to this synergy, we can ensure full control over the production chain.

We offer support at all stages of the production chain according to customers’ specific needs starting from the concept stage, when we can evaluate the product feasibility and provide its specifications, to the various stages of product development, including designing, prototyping and production.

If our customers handle the manufacturing themselves, we can assist in the design phase or supply the necessary components for assembly. Conversely, if they manage the design phase independently, we provide support in both prototyping and production. We also collaborate closely with our customers to assess feasibility, functionality, and potential design simplifications.

MISSION

Our activity and skills concern optical imaging and lighting.

We are committed to providing our customers with the best possible visual experience in all contexts ranging from the urban, interior or museal lighting, up to the medical applications. We can also offer the possibility to extend our visual capacity beyond the visible spectrum, to wavelength ranges that grant access to useful, sometimes vital, information for diagnostic purposes.

As well as granting the highest lighting quality in terms of uniformity, intensity, chromatic output/performance, we aim at offering the best quality in optical imaging. We strive to offer our customers the most effective imaging quality in every field it is required, ranging from camera optics, to microscopy and projection.

HOW WE OPERATE

The design activity develops differently according to the field of application.

Several types of modelling can be used in optics, ranging from the geometric to the physical and the radiometric/photometric ones. Each of them is tailored/suitable for the analysis of how lights and electromagnetic waves behave, as well as for interpreting several phenomena connected to them. Different tools exist in order to deal with each of these areas of analysis.

SOFTWARE SOLUTIONS EMPLOYED

Optical and optomechanical design necessarily involves tailored software solutions, which allow to analyze and optimize the systems of interest and to obtain reliable results. An important part of our resources is invested in software instruments, so that we can always rely on the best tool for each specific sector. Despite this, it may still be necessary in some circumstances to supplement them with specific features, which we autonomously provide for.

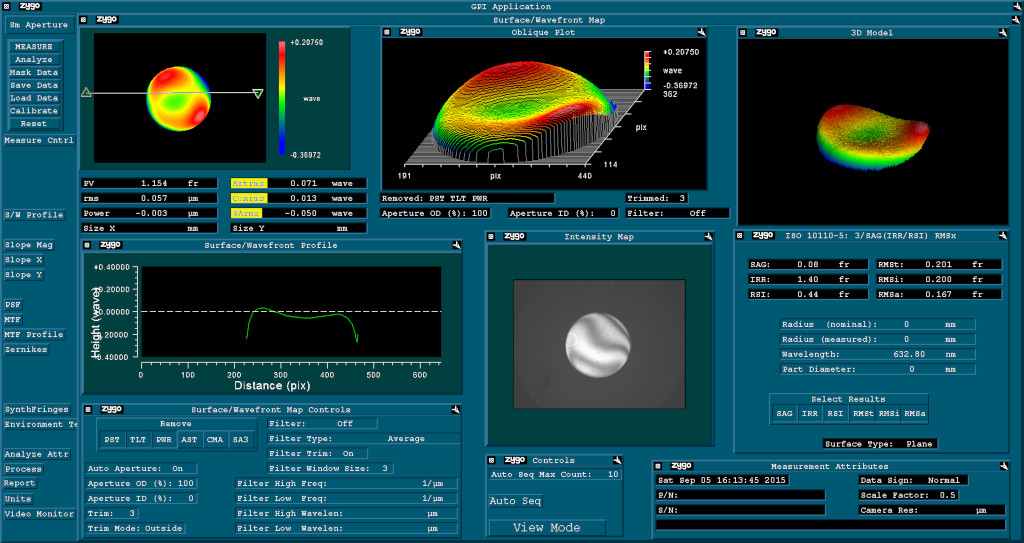

IMAGING OPTICS

In the field of imaging optics, once the project goals are defined, a preliminary paraxial design of the optical system is developed and then processed using Zemax.

The ideal optical system derived from this process defines the focal points, focal plane, and conjugate points of the final model, allowing for the calculation of its magnification.

Once the paraxial analysis is completed, we evaluate the real dimension of the object, considering off-axis aberration and providing their minimization. This optimization activity involves the modification of the power of the optical elements, splitting some of them into additional parts and modifying their positions.

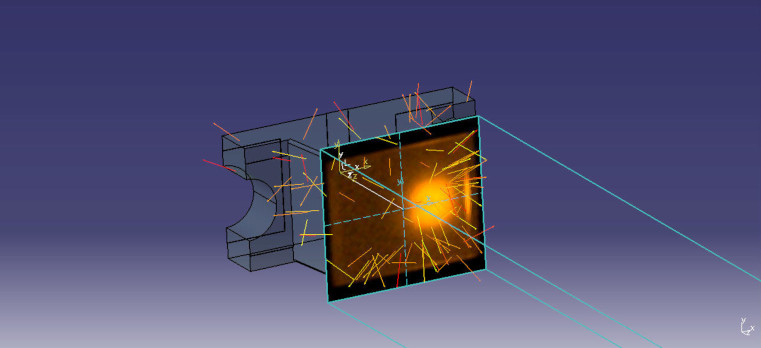

NON IMAGING OPTICS

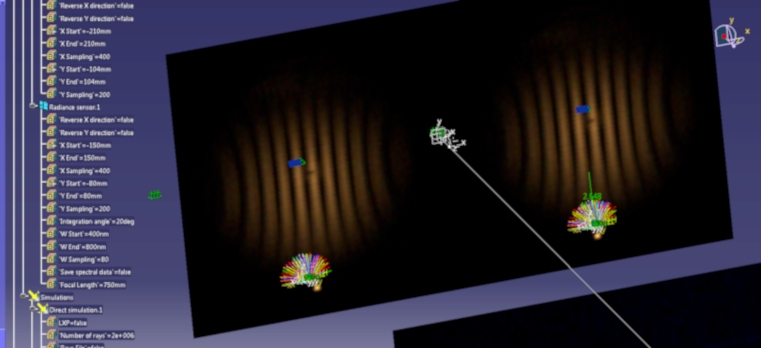

In the case of non-imaging optics, namely systems in which the main objective is represented by the radiative energy transmission, a different approach is required. In such instances, sources are carefully modelled, and radiation is analyzed in the way it interacts with the specific targets. These are firstly modelled in the mechanical CAD, then characterized and simulated in the optical CAD.

In the optimization of the system, the characteristics of the active parts are modified in order to achieve the required illuminance/luminance at the targets.

Depending on the aim of the study, the distribution of irradiance is optimized or, alternatively, the spectral composition or the total amount of energy collected/gathered and emitted/channelled in specific directions.

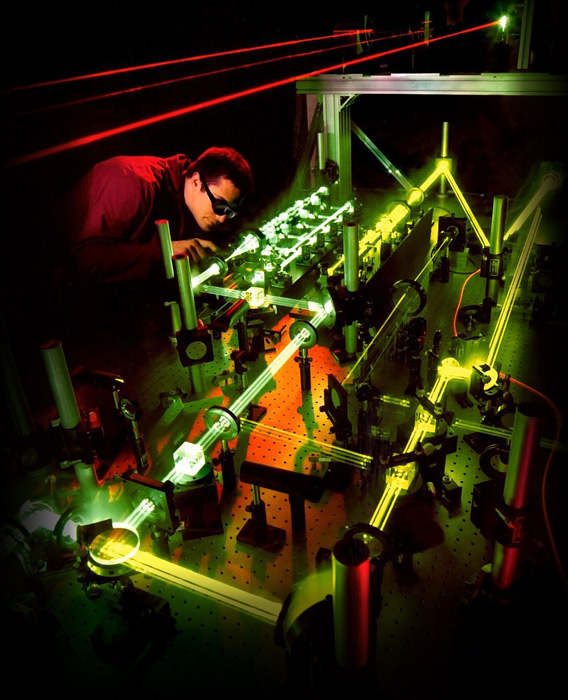

LASER APPLICATIONS

A different approach concerns laser applications, used in “time of flight” systems where the system emits and receives the laser signal within the same device and uses the delay between emitted and received pulse to calculate the object positions.

Lasers, due to their physical characteristics, must be considered separately from illumination systems, and their modelling requires specific instruments and skills.

Several types of lasers exist and Zemax provides for specific modellings for each of them, both in “far field” and “near field”.