PROTOTYPING

From the concept to the real world

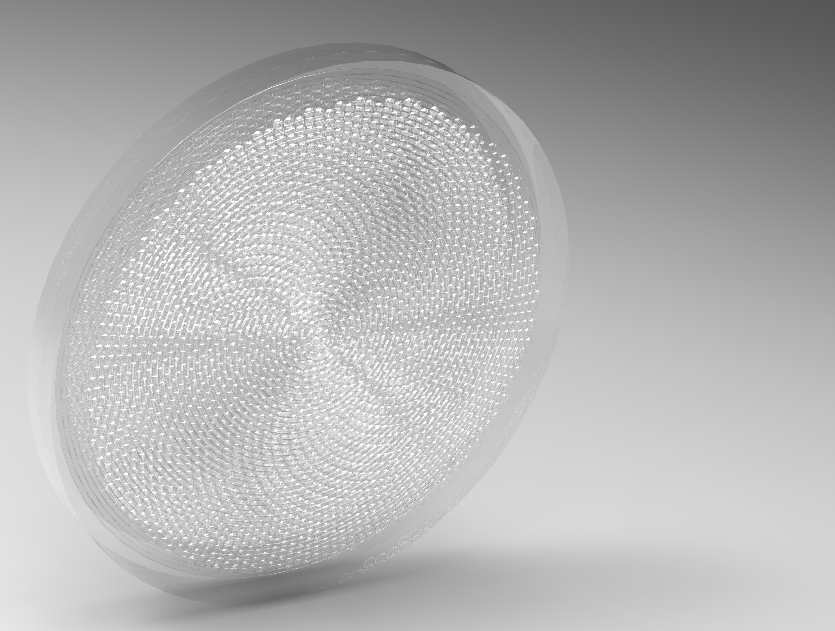

PLASTIC OPTICS PROTOTYPING

We manufacture functional prototypes by diamond turning on a 4 axis synchronized machining center and different types of milling and turning operations with greater accuracy as for the table on the side.

The surface quality obtained by “diamond turning” machining permits to avoid polishing that would affect the surface shape precision. With the same quality and precision of the prototyping we manufacture also the insert for mold in order to obtain for the molded part the same level of precision and surface quality.

| Standard Processing | Diamond Turning | |

|---|---|---|

| Geometrical tolerances |

<10 um |

<10nm |

| P-V tolerance | 10 um | 10nm |

| Surface Roughness | <1um | 1nm |

| Min tool radius | 0.2mm | <50 um |

The diamond turning manufacturing offers the best overall quality of the prototyping but it is a time expansive process, in particular in case of complex and big structures, with the consequence of long leading time and high manufacturing cost. Therefore if more pieces of the same type are required by the specific application, the cost is scaled according to the machining time. For this type of prototyping, where few piaces of the same components are required, we develop chip silicone mold suitable for the task. When more parts are required it is convenient to develop a pilot mold in alluminum suitable to mold some thousands pieces.

In addition to the prototyping of optical parts we offer also the housing/mounding opto-mechanics prototypes made by machining or rapid prototyping, according to the required precision level. Also for this activity we can manage the work flow from the prototyping to the production adopting the appropriate technical solutions in consideration of the quantity and quality expected for the final product.

Glass optics prototyping

In addition to the plastic optics prototyping we manufacture also components in glass both for illumination and imaging. For illumination we can provide cost effective molded glass solution while for imaging we provide components made by classical polishing procedure on standard test plate or by diamond turning for hi-end applications