SINGLE LENSES

AND DOUBLETS

convex and concave spherical lenses, aspherical lenses

cylindrical lenses

Do you have doubts about which components to use and what tolerances to require for your specific application? Are you unsure about the functionality of your optical system. If you want, we can verify that your design meets the requirements, evaluate the tolerances needed, and support you in opto-mechanical integration. We have 30 years of experience in developing optical systems so we can evaluate the functionality of your design, follow you in choosing and characterizing the necessary components. and help you in finalizing your design.

As for the following lenses you will find test plates available and we can help you in fitting, subject to the possibility of making new shapes if necessary. However, it is worth remembering that better performance is achieved by using existing test plates whose characteristics are known accurately, rather than developing new ones where a shape tolerance will certainly have to be taken into account.

PLANO-CONVEX LENSES

Diameter: 1mm-250mm

Clear aperture : 90%

Shape tolerances: 3/2 (0.5)

Flatness = < λ/5 @ 633nm

Centering = 3′ (STD) – 1′ (HQ)

Surface quality : 60/40 (STD) , 40/20 (HQ)

Dimensional tolerances : DIA 0/-0.1, THK +/-0.05mm

Coating : BBAR R<0.5 in 400-680nm e AOI = 0°

BICONVEX LENSES

Diameter: 1mm-250mm

Clear aperture : 90%

Shape tolerances: 3/2 (0.5)

Centering = 3′ (STD) – 1′ (HQ)

Surface quality : 60/40 (STD) , 40/20 (HQ)

Dimensional tolerances : DIA 0/-0.1, THK +/-0.05mm

Coating : BBAR R<0.5 in 400-680nm e AOI = 0°

LENTI PLANO-CONCAVE (PCV)

Diameter: 1mm – 300mm

Surface quality: 60/40, 40/20, 20/10

Flatness = < λ/5 @ 633nm = < λ/5 @ 633nm

Shape error: λ/2@632.8nm

Centering: <3arc min ~ 30arc sec

Chamfer <0.2 millimetri × 45

LENTI BICONCAVE (BCV)

Diameter: 1mm – 300mm 0/-0.1 (<0.2% if DIA<10mm)

Clear aperture > 85% DIA

Surface quality = 60/40, 40/20

Cemtering: <3arc min ~ 30arc sec

Chamfer <0.2 millimetri × 45

DOUBLETS

Composition of two lenses with different refractive index that can partially correct colorimetric aberration. The two glasses have CTEs that are not too different to avoid fracture in thermal cycling.

ASPHERICAL LENSES

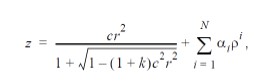

These lenses, used primarily for spherical aberration correction, can be made with varying degrees of precision and relative cost. For applications where particularly high precision is not required they can be made by plastic deformation by compression while for high imaging they can be made by machining with higher costs, related to processing time. These lenses are defined by giving the asphericity coefficients added to the spherical component. The equation defining the aspheric is as follows for even and odd asphere:

CYLINDRICAL LENSES

Material Optical glasses, fused silica, silica, etc.

Diameter: 0.5mm ~ 150mm

Diameter tolerances : 0/-0.1mm

Focal length -50mm ~ 2000mm ±2% (<10mm)

Focal length tolerance : ±0.5%<10mm – 1000mm)

Centration <3 arc min <10 arc sec

Clear aperture >85% ~92% of diameter

Surface quality: 60/40 – 10/5

BALL LENSES

MICRO-LENSES

Micro-optics require tolerances dictated by the specific application. Micro-optics are more complex to manufacture and also require a specific optomechanical structure that does not introduce errors that can significantly penalize optical performance. Again, we can support you and perform a tolerance analysis for you so that the required optical performance is guaranteed.

Lenti per applicazioni IR

Sono lenti realizzate in Silicon, Germanium, CaF2, MgF2